MEATBALL PROCESS LINE

You focus on the big day, let us focus on you.

ABOUT MEATBALL PRODUCTION LINE

We proudly present the fully automated meatball boiling line in a Full Option design, utilizing a steam heating system.

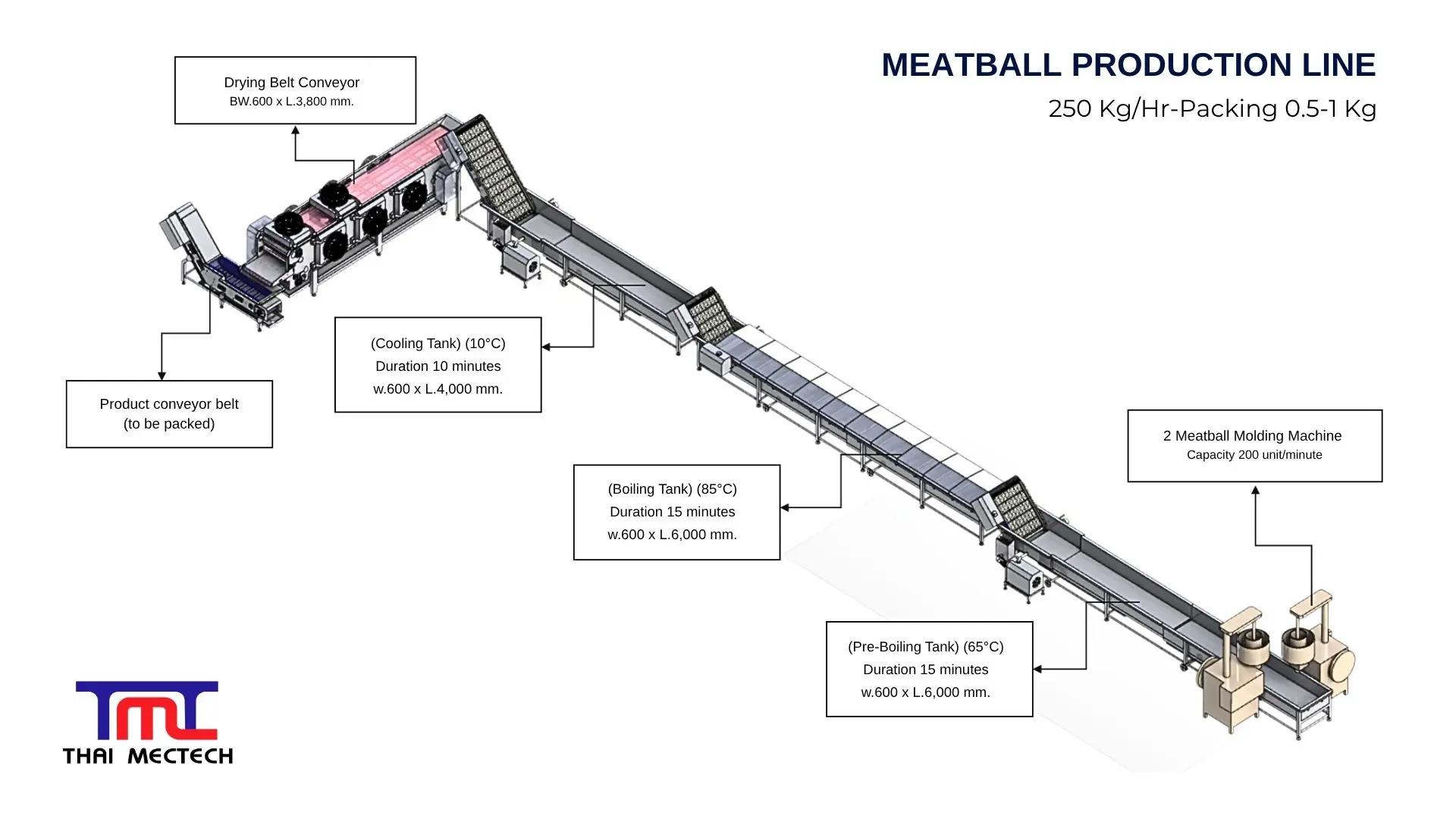

The boiling process in our machine consists of four main stages:

- Meatball setting process

- Meatball boiling process

- Meatball cooling process

- Meatball drying process

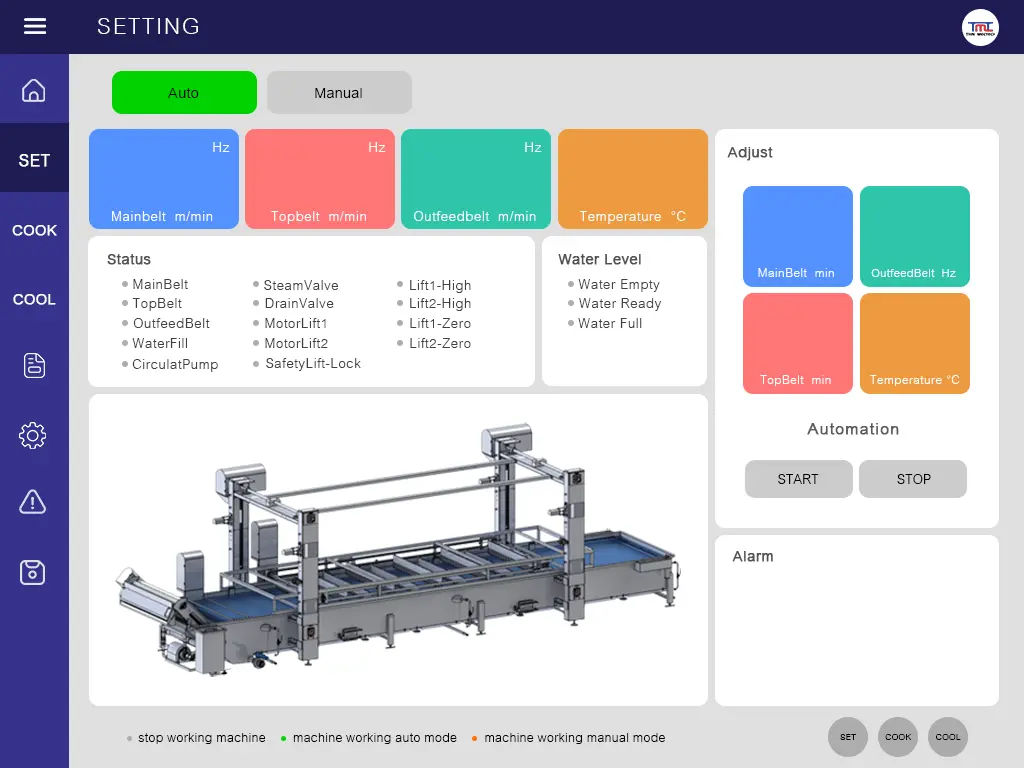

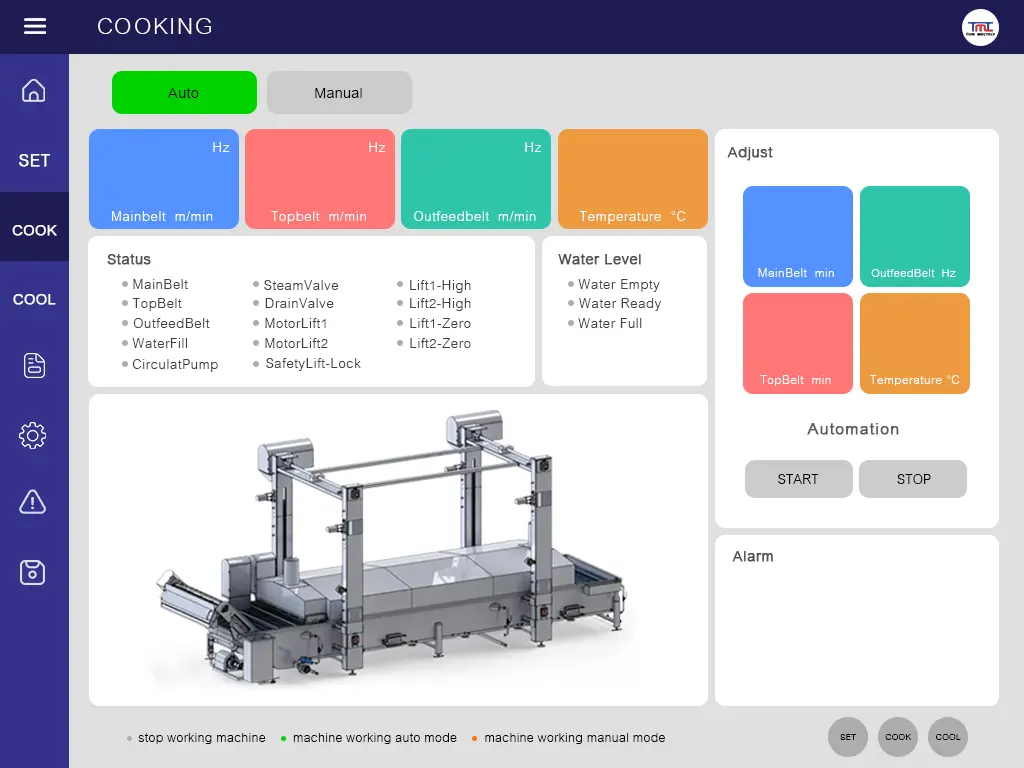

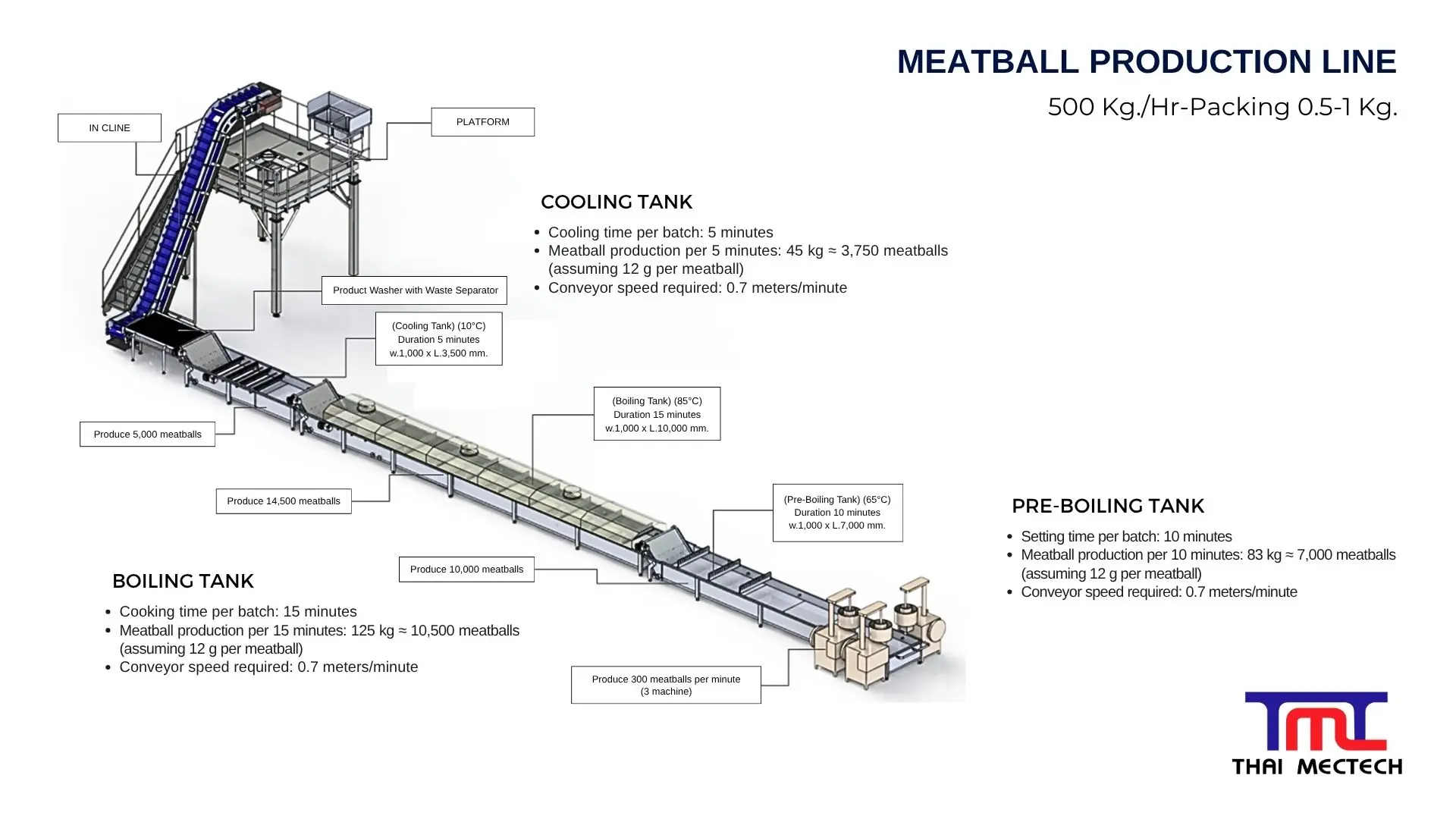

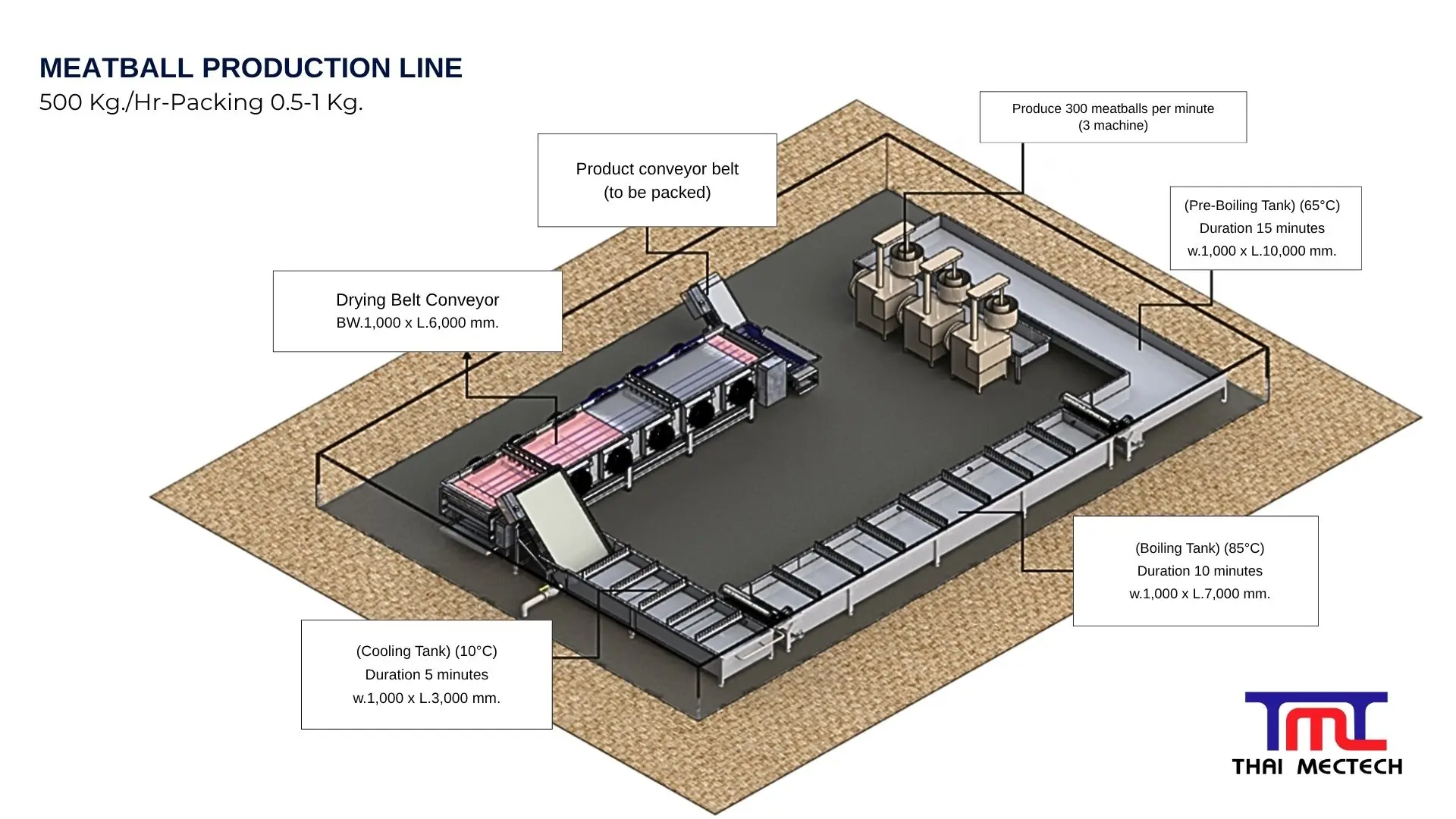

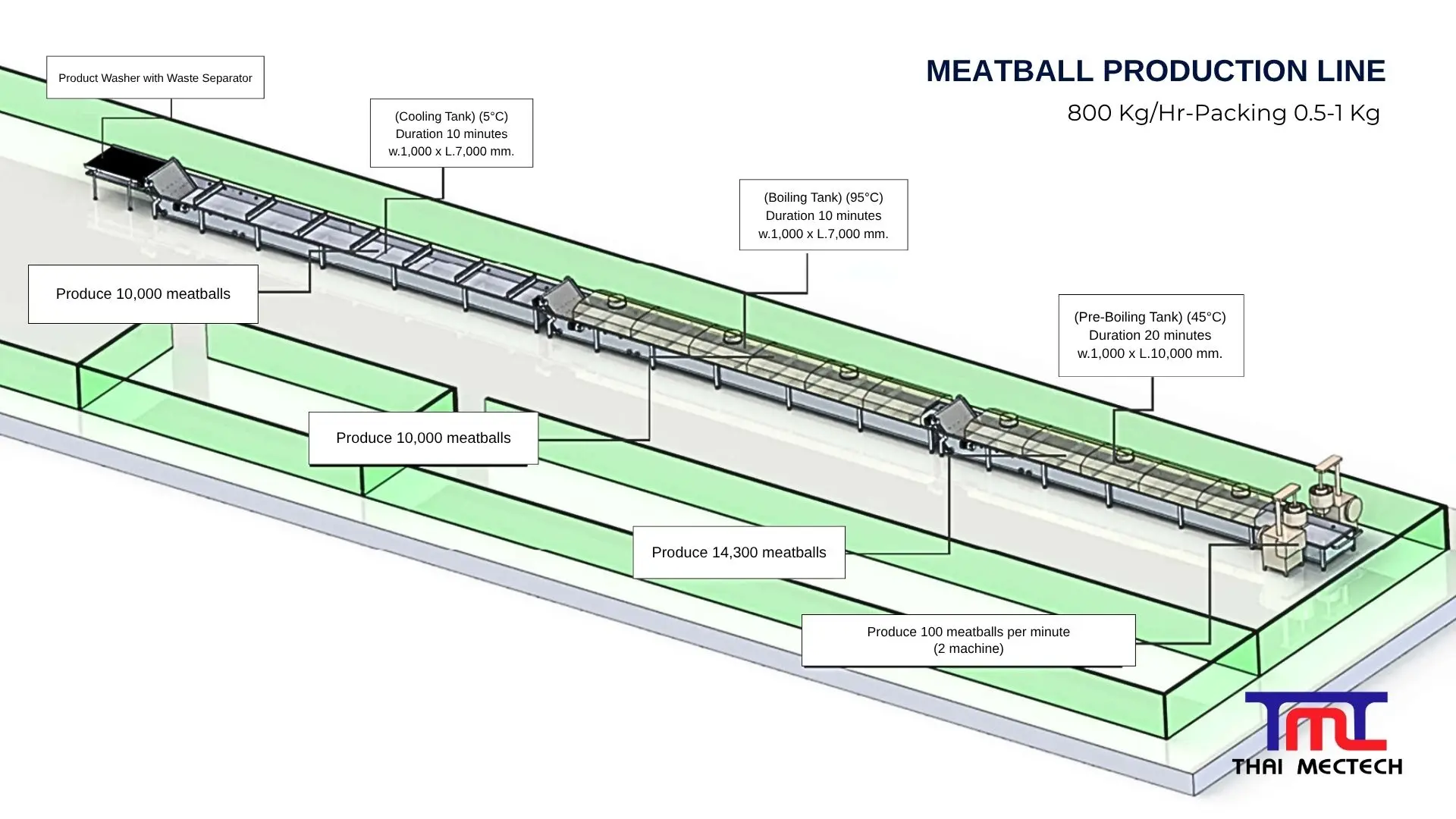

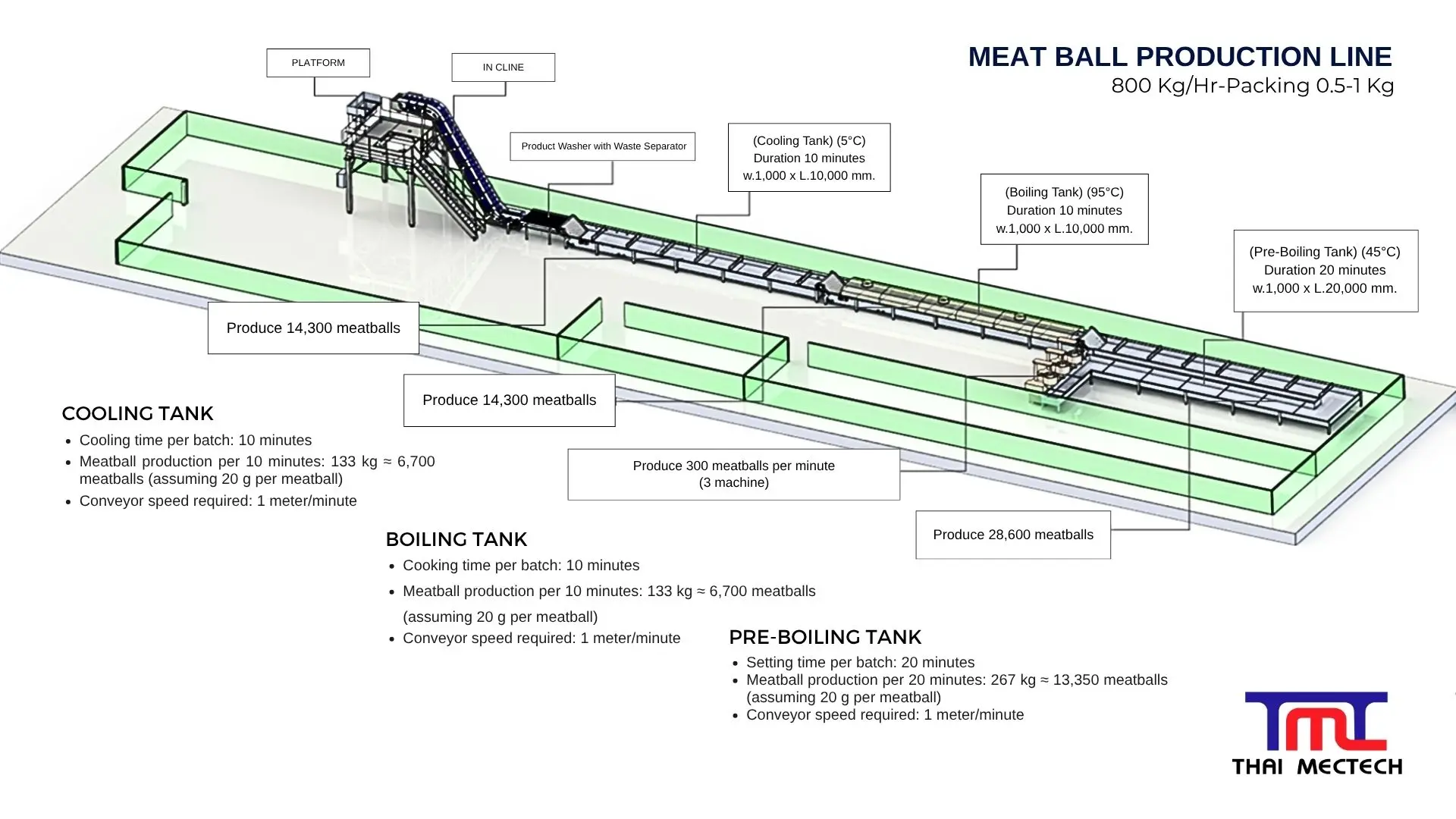

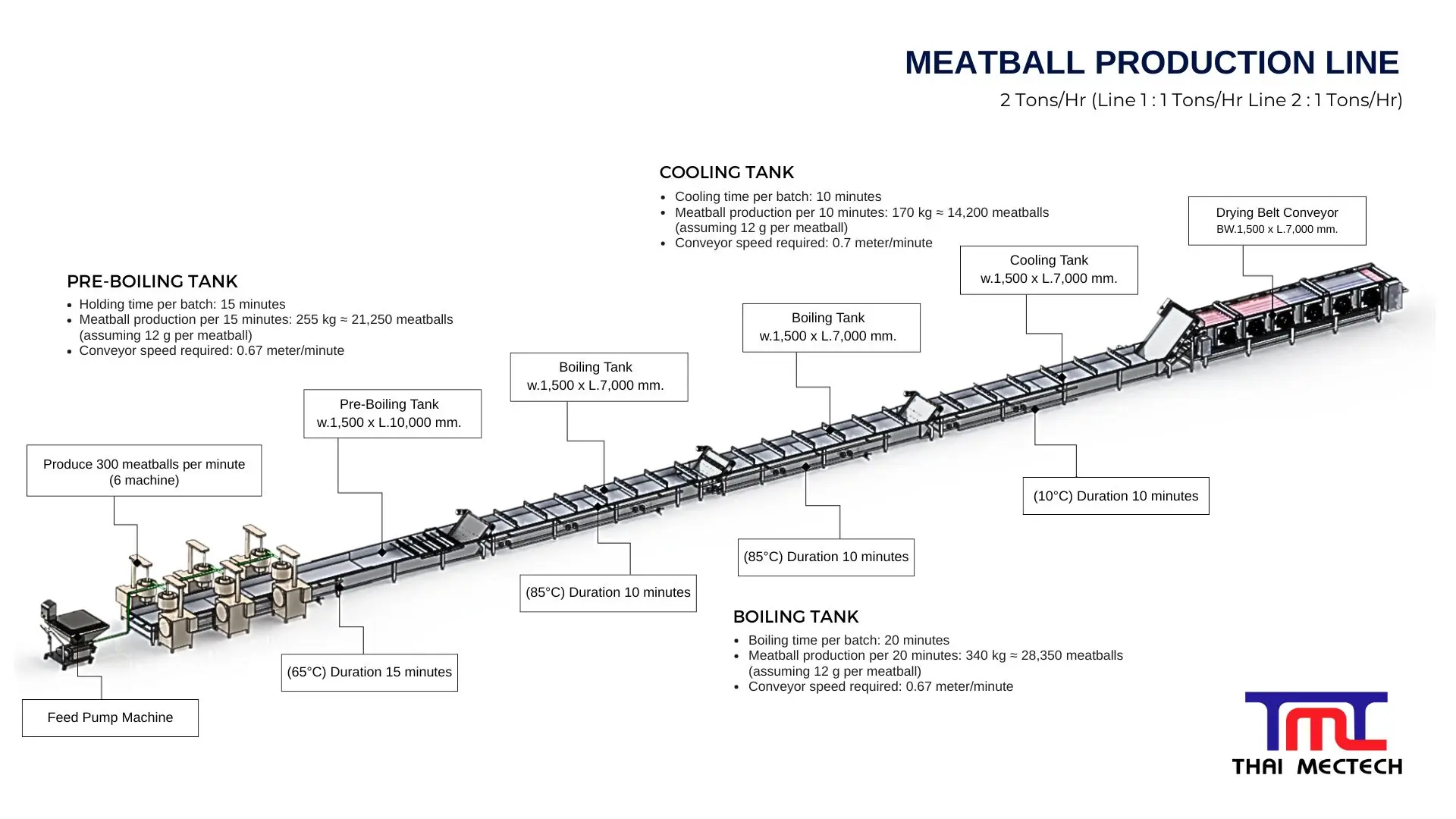

Pre-Boiling Tank

The warm water tank receives the meatballs discharged from the forming machine and allows the semi-liquid meatballs to gradually set under a controlled water temperature (not excessively hot). Proper adjustment of the water temperature and calculation of the residence time in the tank are essential to prevent product damage and to maximize production capacity, thereby utilizing the machine’s performance to its fullest potential.

Boiling Tank

In this step, the water temperature is increased from the warm-water level to fully cook the meatballs (100% doneness). The tank requires proper adjustment of water temperature and calculation of residence time to ensure product quality. Additionally, specific methods such as pressing the meatballs and guiding them through the tank are applied to ensure that every meatball is evenly cooked before being transferred to the next process.

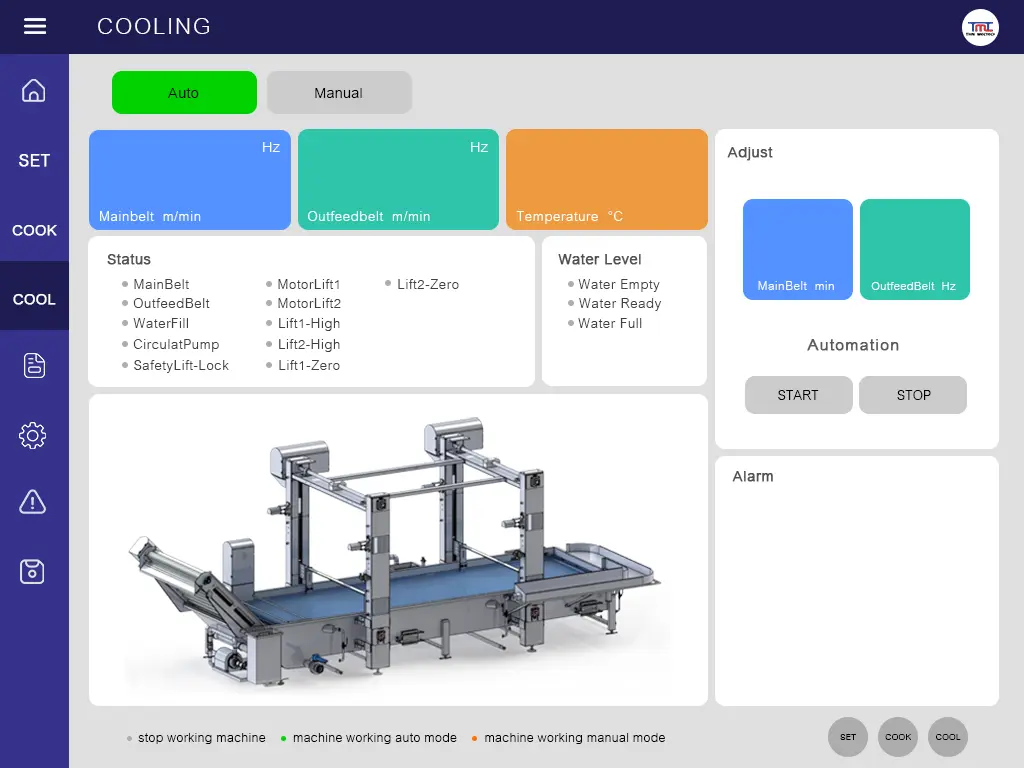

Cooling Tank

In this step, the meatballs coming from the cooking stage still retain relatively high temperatures. The primary function of this process is to reduce the temperature of the meatballs uniformly and consistently. Proper handling and guiding methods are applied to ensure the meatballs are cooled correctly before being transferred to the next stage.

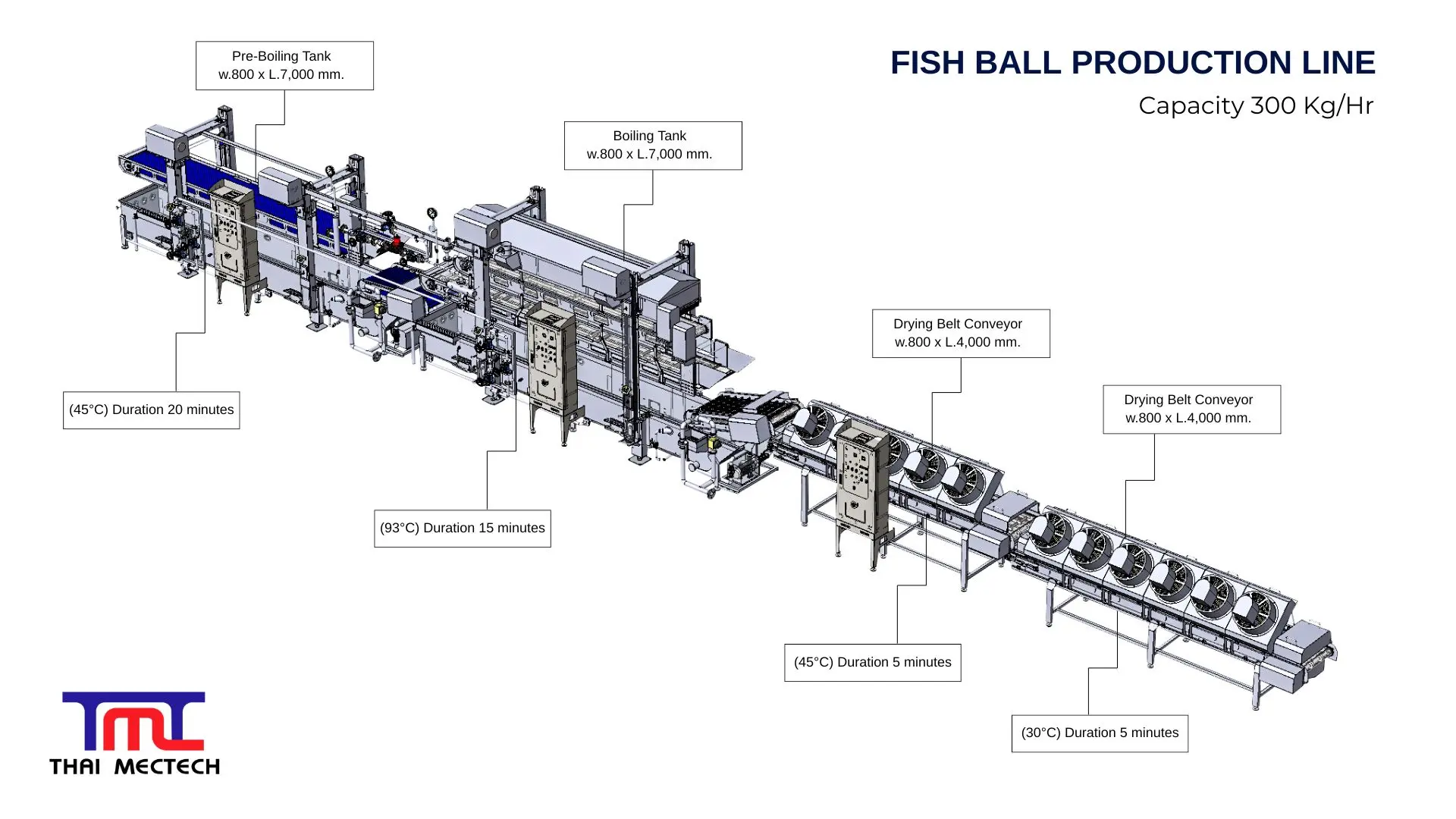

Drying Conveyor

After cooling, the meatballs enter the drying belt conveyor, where specialized fans blow air to remove surface moisture. Depending on the production line design, drying may involve multi-layer conveyors or loop systems to maximize exposure and ensure thorough drying. This stage produces dry, stable meatballs ready for subsequent processes such as packaging or frying. Efficient drying improves product quality, hygiene, and shelf life.

REFERENCE MEAT-BALL PRODUCTION LINE

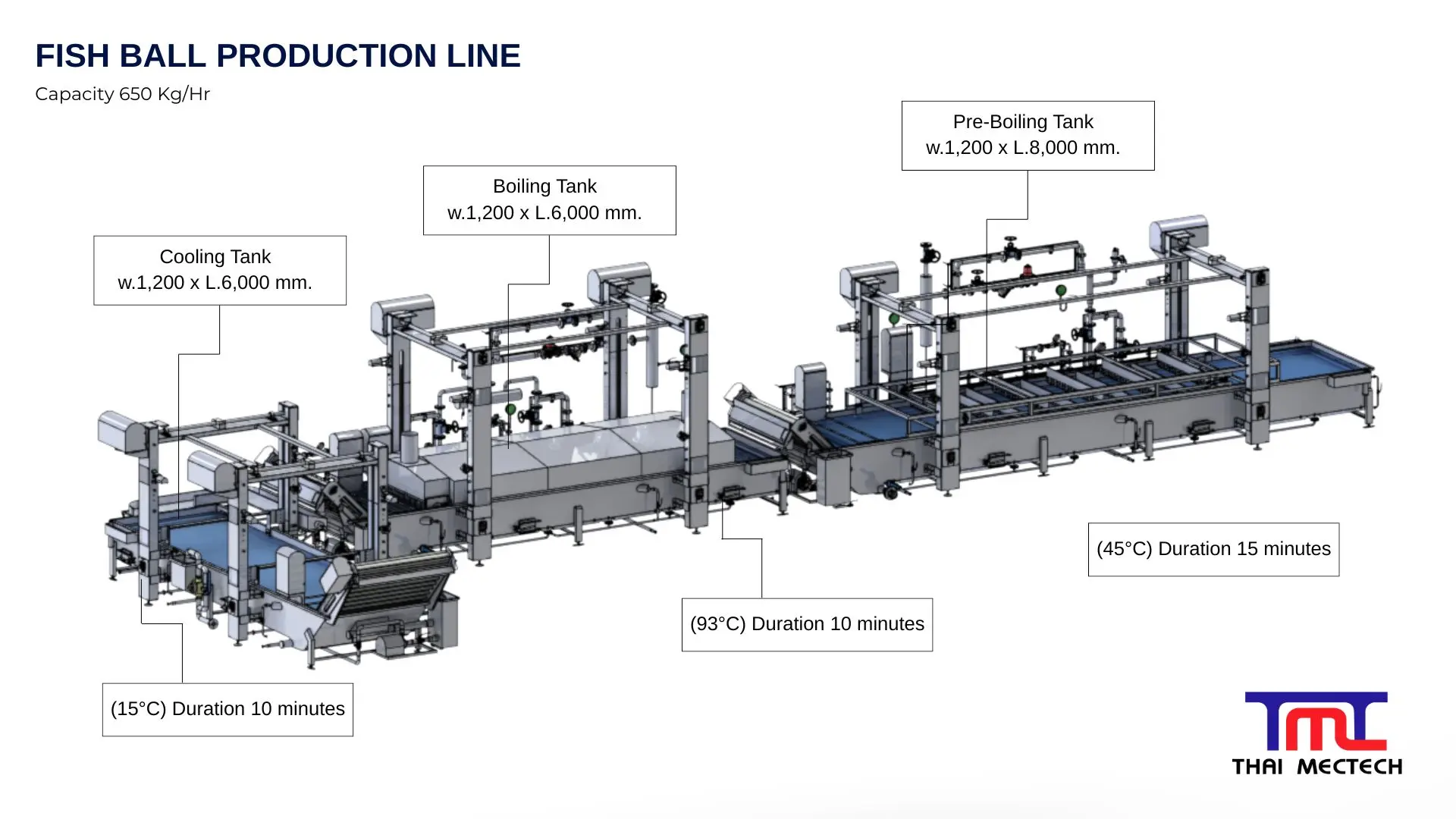

REFERENCE FISH-BALL PRODUCTION LINE

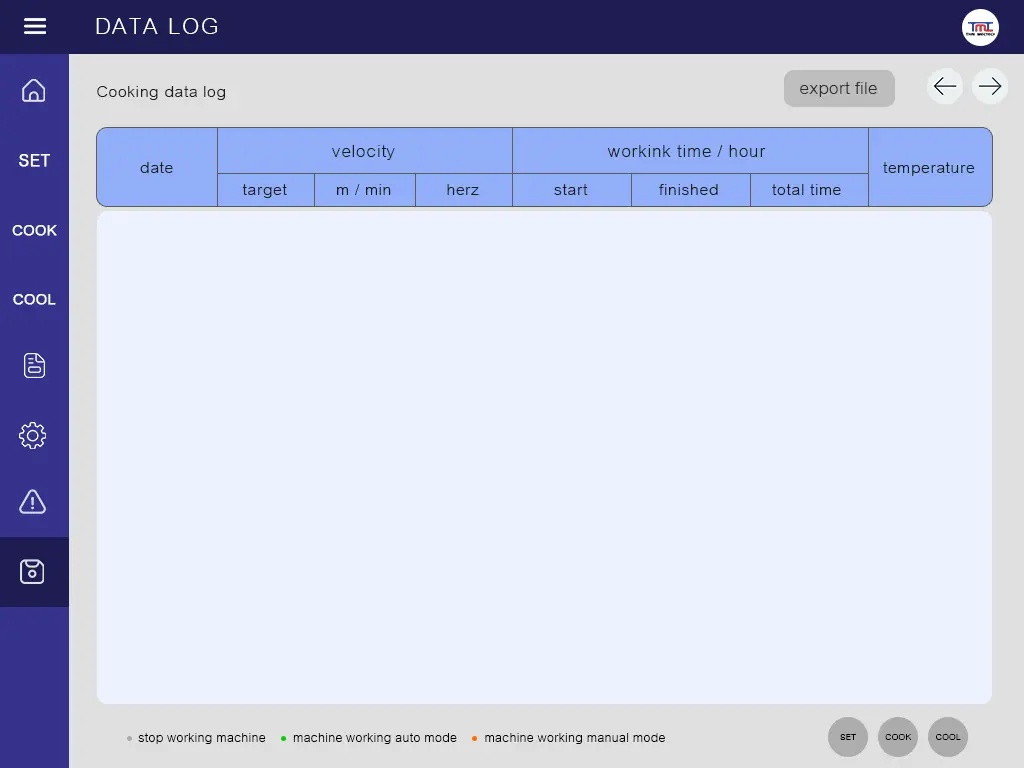

TECHNICAL DATA

MEAT BALL & FISH BALL

PRODUCTTION LINE

CAPACITY 250-1,000 KG/HR

Pre-Boiling (Warm Water) Tank

- Controlled temperature: 45–60 °C

- Holding time: Approximately 20 minutes

Boiling (Hot Water) Tank

- Controlled temperature: 85–90 °C

- Holding time: Approximately 15 minutes

Cooling (Cold Water) Tank

- Controlled temperature: 15–20 °C

- Holding time: Approximately 5–10 minutes

Three-Layer Cooling Conveyor for Meatballs

Meatball Transfer Conveyor to Bagging Table in the Packaging Room

Electrical Control Cabinet for Machine Operation from the Warm Water Tank to the Packaging Room

Machine design compliant with Good Manufacturing Practices (GMP) for proper hygiene

Hygienic design allows quick and simple cleaning

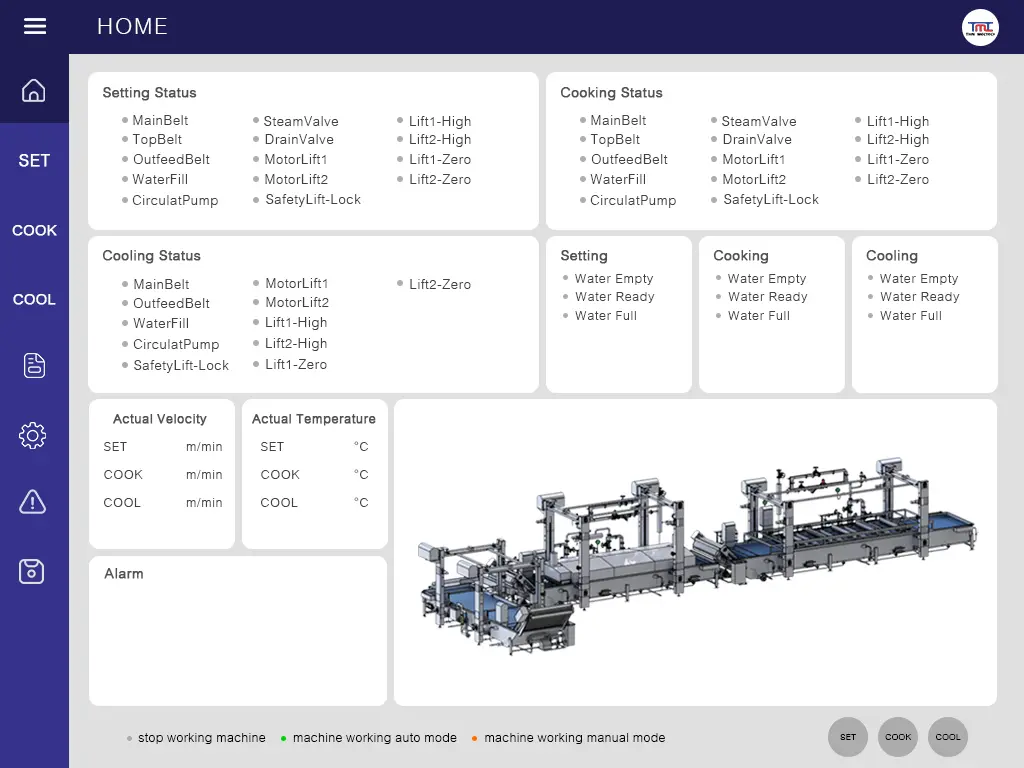

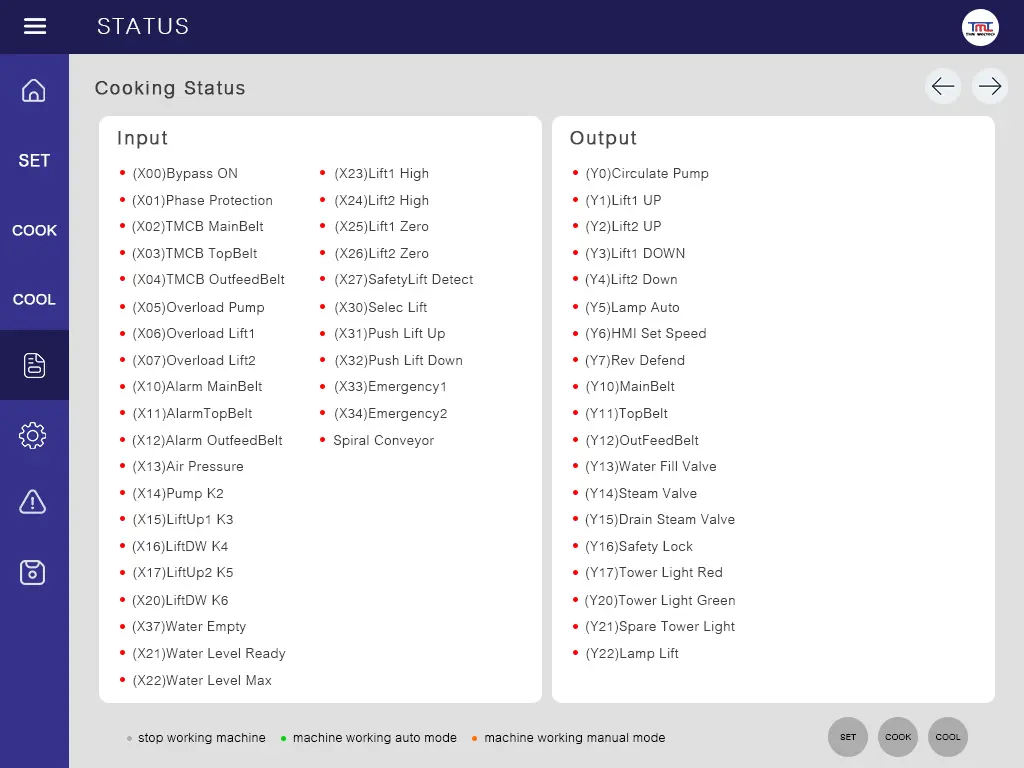

ELECTRICAL CONTROL CABINET

Electrical Control Cabinet

- On/Off switch operation

- Belt speed control switch

- Operation indicator light

- Water temperature display

- Work screen display

- 2 layer waterproof cabinet front cover

- 3 phase electrical system indicator light

- Various factory control settings

- touch screen (Additional functions)

Electrical Equipment

- “ Schneider ” Circuit Breaker

- “ Schneider ” Magnetic Contactor

- “ Danfoss ” Invertor Speed Control

- “ Omron ” Power Relay 24 Vdc

- “ Schneider ” Switch On-Off

- “ Schneider ” Pilot Lamp-Signal

-

“ Motovario ” Gear Motor , Hollow shaft

WARRANTY CONDITIONS

Warranty Conditions

Upon completion of machine installation, our team will perform joint testing with the factory personnel, demonstrate proper machine operation, and provide instructions for routine maintenance to ensure optimal performance and longevity of the equipment.

- Machine warranty for 1 year

- Electrical equipment warranty is 6 months.

- Product warranty conditions after the warranty expires

Warranty conditions are subject to agreement with the customer.